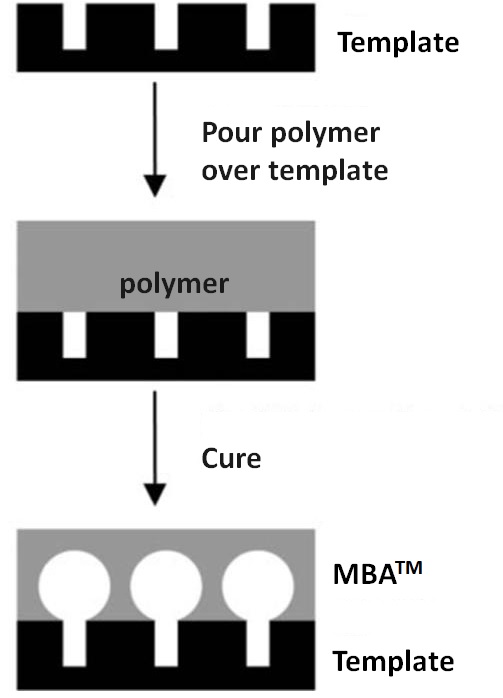

MBA™ Fabrication

Microbubbles (MBs) are spherical compartments with micron diameter openings molded into a biocompatible polymer. Microbubble arrays (MBA™) contain hundreds to thousands of individual MBs per square centimeter. They are formed using high precision semiconductor chip fabrication technology and the patented gas expansion molding (GEM™) process as is illustrated in the adjacent figure and described in Giang et al. Lab on a chip. 2007 7(12):1660-2. Nidus has considerable control, with nanometer resolution, over the GEM™ process. This enables the mass production MBA™ comprised of MBs with different sized openings (pico to nanoliter volumes), opening size & shape, array density (MB/cm2) and MB spacing.

Properties – Competitive Advantage

There are many applications for Nidus MBA™, not only based on our ability to reliably produce such large numbers of consistently dimensioned MBs with the patented GEM™ process, but also based on the unique fluid-flow properties resulting from the spherical shapes. In static cell culture, the spherical geometry and high aspect ratio (AR>2, defined as the MB maximum diameter divided by the MB opening diameter) concentrates cell secreted factors. This create a niche for cells to rapidly condition the media and it serves as a basis for assay development. Importantly, the MB shape hinders dislodgment cells within the MB when the fluid flow results outside the array from either media changes in static culture or from coupling the array to microfluidic flow channel. The illustration below shows one configuration of our arrays for high throughput static culture where the arrays are placed in a 96 well format.

Assays and IMAAT™ Software Tools

Assays have been developed using MBA™ technology for a variety of biomedical applications including cancer research, tissue chip drug screening, and monoclonal antibody discovery. These assays can be performed under static culture or microfluidic flow conditions. A key component to the successful use of MBA™ technology for HTS applications is use of sophisticated suite of IMage data Acquisition and Analysis software Tools (IMAAT™) developed specifically for MBA™ technology. Nidus’s ImAAT™ software is coded in Python and uses convolutional network architectures for fast and precise segmentation of images to enumerate and report out data from each MB in the array. Please contact us if you are interested in using or learning more about IMAAT™ Software.